Key takeaways

Reverse logistics network optimization has emerged as a critical tactic for raising productivity and cutting expenses in today’s cutthroat business environment. Businesses trying to increase customer happiness and streamline operations must comprehend the complexities of reverse logistics, from product returns to recycling. Businesses may create a solid infrastructure that can adjust to shifting demands by focusing on scalability, integrating technology solutions, and prioritizing closeness to customers when developing a strategic network. Further improving visibility and streamlining procedures can be achieved by implementing technological solutions like data analytics and tracking systems. Through the implementation of workflow optimization, standardization of procedures, and continual improvement, enterprises may guarantee optimal performance of their reverse logistics network. For the purpose of promoting continuous development and providing outstanding service, it is imperative to measure success using key performance indicators and give priority to customer happiness. By emphasizing efficiency, economy, and customer-focused design, companies may create a reverse logistics network that not only satisfies but surpasses expectations.

Understanding Reverse Logistics

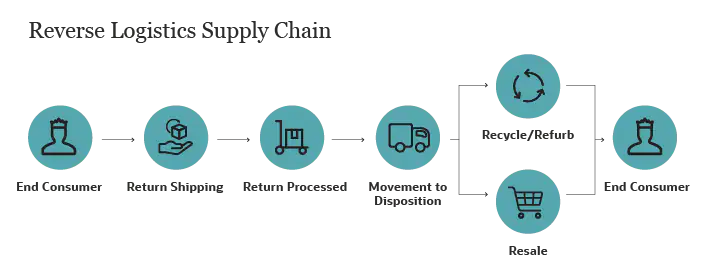

The process of controlling the movement of goods or materials from their final location back to their point of origin is known as reverse logistics. It entails tasks including product exchanges, maintenance, recycling, and renovation. Businesses must comprehend reverse logistics in order to manage these procedures efficiently and cut expenses.

Recognizing the effect reverse logistics can have on customer satisfaction is a crucial component of comprehending reverse logistics. Through effective return and exchange management, companies may improve customer satisfaction and foster customer loyalty.

The advantages reverse logistics might have for the environment are another crucial factor. Businesses can employ sustainable practices, such recycling and refurbishment, to cut waste and make a positive impact on the environment.

In order to understand reverse logistics in depth, it is essential to analyze the various stages involved in the process, including product collection, transportation, sorting, and disposition. By gaining a comprehensive understanding of these stages, businesses can identify areas for improvement and optimize their reverse logistics network.

Designing a Strategic Network

Designing a strategic reverse logistics network involves carefully planning the physical infrastructure required to support efficient operations. This includes determining the optimal locations for processing centers, warehouses, and transportation hubs.

One important consideration in designing a strategic network is proximity to customers and suppliers. By locating processing centers and warehouses close to major customer hubs, businesses can reduce transportation costs and improve delivery times.

Another aspect to consider is the integration of technology and automation in the network design. By leveraging advanced technologies such as robotics and artificial intelligence, businesses can streamline processes and improve overall efficiency.

Designing a strategic network also involves considering the scalability and flexibility of the infrastructure. By anticipating future growth and changes in demand, businesses can ensure that their reverse logistics network can adapt and expand as needed.

Overall, designing a strategic network requires a thorough analysis of the business’s unique requirements and goals. By aligning the network design with these factors, businesses can build a reverse logistics infrastructure that is efficient, cost-effective, and customer-centric.

Implementing Technology Solutions

Implementing technology solutions is essential for optimizing a reverse logistics network. By leveraging the power of technology, businesses can automate processes, improve visibility, and enhance overall efficiency.

One key technology solution for reverse logistics is the use of tracking and tracing systems. By implementing these systems, businesses can monitor the movement of products throughout the network, ensuring timely and accurate delivery.

Another important technology solution is the use of data analytics. By collecting and analyzing data related to reverse logistics operations, businesses can gain valuable insights and identify areas for improvement. This can help in optimizing processes, reducing costs, and enhancing customer satisfaction.

Additionally, businesses can benefit from implementing inventory management systems that provide real-time visibility into product availability and location. This enables better planning and coordination of reverse logistics activities.

Overall, implementing technology solutions in a reverse logistics network can significantly enhance efficiency, reduce costs, and improve customer satisfaction. By leveraging the right tools and systems, businesses can stay ahead in the competitive landscape and deliver a superior reverse logistics experience.

Optimizing Processes and Workflows

Optimizing processes and workflows is crucial for building an efficient reverse logistics network. By analyzing existing processes and identifying bottlenecks, businesses can streamline operations and improve overall efficiency.

One key aspect of optimizing processes is standardizing procedures. By establishing clear guidelines and standard operating procedures, businesses can ensure consistency and minimize errors.

Another important factor in optimizing processes is the use of lean principles. By eliminating waste and reducing unnecessary steps, businesses can improve efficiency and reduce costs.

Furthermore, businesses can benefit from implementing efficient sorting and disposition systems. By utilizing automated technologies and intelligent algorithms, products can be sorted and routed to the appropriate destinations quickly and accurately.

Continuous improvement is also a critical aspect of optimizing processes and workflows. By regularly evaluating performance metrics and soliciting feedback from customers and employees, businesses can identify areas for improvement and implement necessary changes.

Overall, optimizing processes and workflows is an ongoing effort that requires a commitment to continuous improvement. By focusing on efficiency, accuracy, and customer satisfaction, businesses can build a reverse logistics network that is highly efficient and cost-effective.

Measuring Success and Continuous Improvement

Measuring success and continuous improvement is essential for ensuring the long-term effectiveness of a reverse logistics network. By establishing key performance indicators (KPIs) and regularly monitoring them, businesses can track their progress and identify areas for further optimization.

One important KPI to consider is the percentage of returned products successfully processed and resolved within a specific timeframe. By aiming for a high percentage, businesses can demonstrate their commitment to efficient and timely reverse logistics operations.

Another critical KPI is the cost per return. By tracking the costs associated with reverse logistics activities, businesses can identify opportunities for cost reduction and process improvement.

Customer satisfaction is another key metric to measure. By collecting feedback from customers and monitoring their satisfaction levels, businesses can identify areas for improvement and enhance the overall customer experience.

Continuous improvement is a fundamental aspect of measuring success in a reverse logistics network. By regularly reviewing performance metrics, identifying trends, and implementing necessary changes, businesses can stay ahead of the competition and deliver exceptional reverse logistics services.

In conclusion, measuring success and continuously improving a reverse logistics network is crucial for achieving operational excellence. By setting clear goals, monitoring performance, and implementing necessary changes, businesses can enhance efficiency, reduce costs, and provide a superior customer experience.

Conclusion

In conclusion, understanding reverse logistics and designing a strategic network are essential components for businesses looking to streamline their operations and enhance customer satisfaction. By implementing technology solutions, optimizing processes and workflows, and continuously measuring success and driving improvements, businesses can build a robust reverse logistics network that exceeds expectations. With a focus on efficiency, cost-effectiveness, and customer-centricity, businesses can ensure their reverse logistics operations operate at peak efficiency and deliver exceptional service. By prioritizing customer satisfaction and embracing continuous improvement, businesses can stay ahead in the competitive landscape and provide a superior reverse logistics experience.

FAQ

How do you create a reverse logistics system?

Creating a reverse logistics system involves a strategic approach that focuses on efficiency, cost-effectiveness, and customer satisfaction. To build a successful reverse logistics network, businesses should start by understanding the key concepts and processes involved in reverse logistics. This includes managing product returns, repairs, recycling, and refurbishment in a way that minimizes costs and maximizes customer satisfaction.

Once the basics of reverse logistics are understood, the next step is to design a strategic network. This involves carefully planning the physical infrastructure, such as processing centers, warehouses, and transportation hubs, and considering factors like proximity to customers and suppliers, scalability, and flexibility. By strategically designing the network, businesses can optimize operations and improve overall efficiency.

Implementing technology solutions is another crucial step in creating a reverse logistics system. By leveraging technology such as tracking and tracing systems, data analytics, and inventory management systems, businesses can automate processes, improve visibility, and enhance efficiency. These technological tools play a key role in optimizing operations and reducing costs.

Optimizing processes and workflows is also essential in creating a successful reverse logistics system. By standardizing procedures, implementing lean principles, and utilizing efficient sorting and disposition systems, businesses can streamline operations and improve accuracy. Continuous improvement is key in this step, as businesses should regularly evaluate performance metrics and make necessary changes to enhance efficiency.

Measuring success and driving continuous improvement are the final steps in creating a reverse logistics system. By establishing key performance indicators, monitoring performance, and focusing on customer satisfaction, businesses can track their progress and identify areas for further optimization. By prioritizing operational excellence, businesses can ensure that their reverse logistics system operates at peak efficiency and delivers exceptional service.

What are the five drivers of reverse logistics?

The five drivers of reverse logistics are key factors that influence the efficiency and effectiveness of a reverse logistics system. These drivers include product returns, repairs, recycling, refurbishment, and end-of-life disposal.

Product returns are a common driver of reverse logistics, as businesses must efficiently process returned items and determine the most appropriate disposition for each product. Repairs involve fixing defective or damaged items to return them to a saleable condition, reducing waste and increasing customer satisfaction.

Recycling is another important driver, as businesses must responsibly dispose of materials that cannot be reused or refurbished. Refurbishment involves restoring products to like-new condition, extending their lifecycle and reducing the need for new production.

End-of-life disposal is the final driver, requiring businesses to properly dispose of products that can no longer be used or repaired. By effectively managing these five drivers, businesses can optimize their reverse logistics operations and enhance customer satisfaction.

What is reverse logistics PDF?

A reverse logistics PDF is a document that provides detailed information and guidelines on the concept of reverse logistics. This PDF typically includes information on managing product returns, repairs, recycling, refurbishment, and end-of-life disposal. It serves as a valuable resource for businesses looking to understand and implement effective reverse logistics strategies. By referring to a reverse logistics PDF, businesses can gain insights into best practices, industry trends, and key drivers of reverse logistics, ultimately helping them optimize their operations and enhance customer satisfaction.

I hope this article was helpful for more checkout our previous blogpost by clinking here