key takeaways

Optimizing reverse supply chain management is becoming more than simply a trend for businesses hoping to achieve sustainable growth and profitability in today’s cutthroat business environment. Businesses may save expenses while simultaneously advancing circular economy principles and strengthening their sustainability initiatives by comprehending the challenges associated with handling product returns, recycling, and remanufacturing. Reverse supply chain activities must be streamlined in order to overcome obstacles and adopt cutting-edge technology like AI and IoT. Businesses may monitor the effectiveness of their sustainability programs and make data-driven decisions that will lead to long-term financial and environmental advantages by analyzing key performance indicators and continuously improving procedures. Reverse logistics techniques will be integrated into business in the future to recover value from returned goods, cut waste, and contribute to a more sustainable economy.

introduction

Understanding the nuances of reverse supply chain management is essential to achieving sustainable growth and profitability in the quickly changing business environment of today. Businesses may cut waste and recover value from returned goods by streamlining the flow of materials and goods from customers back to the producer. Reverse logistics techniques have many advantages, such as lower costs, improved environmental initiatives, and the encouragement of circular economy activities. However, creative solutions and cutting-edge technologies like IoT and AI are needed to navigate the difficulties of managing a variety of product returns and encouraging cooperation among stakeholders. Adopting the principles of reverse logistics management can clear the path for long-term financial and environmental benefits as companies look to gauge their success through KPIs.

Understanding Reverse Supply Chain Management

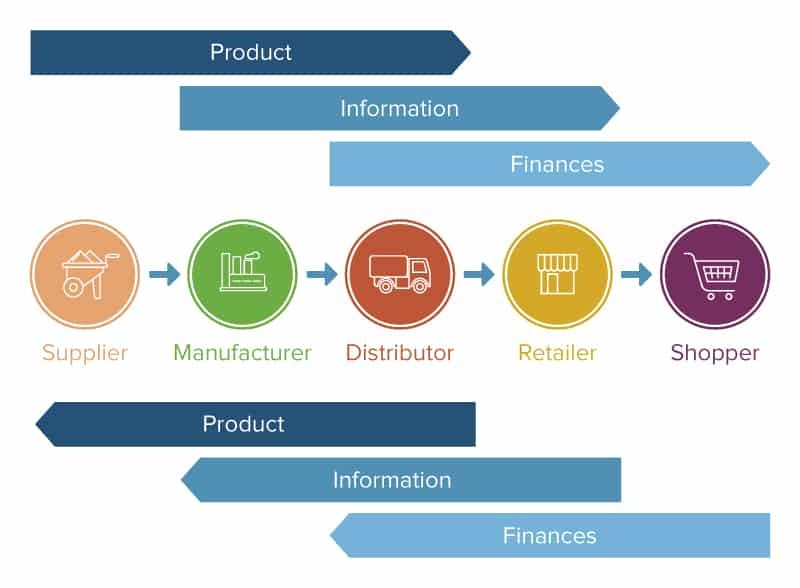

Managing the movement of products and materials from the final customer back to the supplier or producer is known as reverse logistics management.

It covers things like recycling, remanufacturing, disposal, and product returns.

Businesses can find ways to increase productivity, cut down on waste, and optimize value by knowing the nuances of reverse logistics management.

The fundamental ideas and ideas of reverse logistics management will be covered in this part.

Benefits of Implementing Reverse Supply Chain Strategies

Businesses can gain a number of advantages by putting reverse logistics tactics into practice.

The ability to cut expenses by making the most use of returned goods and materials is one of the key benefits.

Enterprises can retrieve value from products that were previously wasted by putting in place effective procedures for product returns, recycling, and remanufacturing.

Reverse supply chain management can also improve sustainability initiatives by encouraging circular economy principles and cutting waste.

The numerous advantages that companies can reap by putting reverse logistics strategies into practice will be covered in detail in this section.

Challenges and Solutions in Reverse Supply Chain Management

Reverse logistics management has a number of advantages, but it also has several drawbacks.

The intricacy of handling a variety of product returns and making sure that they are properly sorted and disposed of is one of the biggest obstacles.

Effective coordination and communication between multiple parties, such as suppliers, customers, and logistics companies, is another difficulty.

Nevertheless, companies may overcome these obstacles and improve the efficiency of their reverse supply chain operations by using best practices and solutions.

The common issues in reverse logistics management will be covered in this part, along with workable solutions.

Innovative Technologies Revolutionizing Reverse Supply Chain Processes

Technology has drastically changed the way reverse logistics operations are carried out.

A number of cutting-edge technologies, including blockchain, artificial intelligence (AI), and the Internet of Things (IoT), are completely changing how companies handle product returns, recycling, and remanufacturing.

These technologies allow for automated sorting and disposition, improved visibility and transparency across the reverse supply chain, and real-time tracking and tracing of returned goods.

This section will examine the state-of-the-art technologies and their advantages for organizations as they transform reverse logistics procedures.

Measuring Success: Key Performance Indicators for Reverse Supply Chain

In order to evaluate the efficacy of reverse logistics management, companies must set up key performance indicators (KPIs) to track progress.

Metrics like customer satisfaction, cost savings, recovery, recycling, and return rates can all be included in these KPIs.

Businesses can enhance their reverse supply chain operations by identifying areas for improvement and making data-driven decisions by routinely monitoring and analyzing these KPIs.

The key performance indicators (KPIs) that companies should take into account when assessing the efficacy of their reverse logistics initiatives are covered in this section.

Conclusion

In summary, improving reverse supply chain management is essential for a company’s sustainability and profitability. It’s not merely a way to save expenses and boost productivity. Innovative technologies such as IoT and AI can help firms solve the hurdles of managing a variety of product returns and encouraging stakeholder participation. Reverse supply chain management’s tenets have long-term advantages for the environment and the bottom line. Businesses may monitor the effectiveness of their sustainability initiatives and make well-informed decisions to improve operations by tracking key performance indicators and continuously refining processes. Reverse supply chain methods that integrate waste reduction, circular economy principles, and value recovery from returned goods are the way of the future for company.

FAQ

How can reverse logistics supply chains be more sustainable?

Eco-friendly methods can be used across the reverse logistics supply chain to increase sustainability. This entails cutting waste by effectively returning products, encouraging recycling and remanufacturing to prolong the life of resources, and working with partners and suppliers that are equally committed to sustainability. Businesses can greatly lessen their environmental impact by utilizing biodegradable packaging materials, integrating renewable energy sources, and planning transportation routes to limit carbon emissions. Using sustainability in reverse logistics improves company reputation and draws in eco-aware customers in addition to being good for the environment. Through the implementation of a sustainable supply chain strategy, companies may foster a more circular economy and help ensure a more environmentally friendly future for future generations.

What is reverse supply chain management?

The process of effectively controlling the movement of resources and goods from the final customer back to the supplier or manufacturer is known as reverse logistics management. It entails managing tasks like product returns, recycling, remanufacturing, and disposal in an environmentally conscious and thoughtful way. Businesses can lower costs and recover value from returned goods while simultaneously encouraging circular economy practices and environmental sustainability through the optimization of reverse logistics management. This all-encompassing strategy for handling the reverse flow of goods is essential for improving the effectiveness of the logistics and developing a more viable and successful business plan.

How can reverse logistics improve supply chain efficiency?

By streamlining the flow of materials and goods from final consumers back to manufacturers or suppliers, reverse logistics plays a critical role in increasing the efficiency of the supply chain. Businesses may improve sustainability initiatives, cut expenses, and streamline operations by handling product returns, recycling, remanufacturing, and disposal. Reverse logistics strategies that are effective help businesses maximize value from returned goods, reduce waste, and advance circular economy principles. This improves the performance and profitability of the supply chain as a whole while also helping the environment. Reverse logistics can result in higher customer satisfaction, shorter lead times, and increased efficiency when it is embraced as a crucial part of supply chain management. Through the use of reverse logistics techniques, enterprises may establish a more robust and sustainable logistics that fosters sustained success.

What are the benefits to organizations when they control their reverse supply chain?

Organizations can gain many advantages that support their overall performance and sustainability when they have control over their reverse logistics. Businesses can establish effective procedures for product returns, recycling, remanufacturing, and disposal by managing the movement of goods and materials from customers back to the producer. With the use of this control, they can save expenses, maximize the use of returned goods and materials, and salvage value from previously rejected objects. In addition, firms can improve their sustainability initiatives, cut waste, and advance circular economy principles by effectively managing their reverse logistics. All things considered, firms can increase productivity, profitability, and show their commitment to environmental responsibility by controlling the reverse logistics.

Hope this article was helpful for more check out our previous blog post by clicking here