Reverse logistics is the process of moving goods from the end customer back to the retailer or manufacturer. This process includes the handling of returns, unsold goods, end-of-life products, and packaging management. Reverse logistics is important for companies to have because it helps them reduce costs, create value, decrease risk, and complete the product life cycle. By having an efficient reverse logistics system in place, companies can save costs related to transportation, administration, repairs, tech support, quality assurance, marketing, and disposal. Reverse logistics also offers businesses an opportunity to meet sustainability targets by repairing, refurbishing, and recycling products, which diverts them from ending up in landfills. Additionally, handling returns is a big pain point for e-commerce businesses, but key to building customer loyalty. In fact, 67% of consumers will check an online retailer’s return policy before committing to a purchase, so an efficient reverse logistics operation will help your business win more sales.

Manage returns, repairs, and refurbishment internally

Managing returns, repairs, and refurbishment internally can be a complex and challenging process for companies. It requires significant investment in resources, infrastructure, and expertise to handle the entire reverse logistics process, from receiving the returned products to refurbishing them and reselling them. Companies that manage returns internally must have a clear understanding of their customers’ needs and preferences, as well as the ability to manage inventory, track shipments, and process payments. They must also have the necessary technology and software to manage the entire process efficiently and effectively.

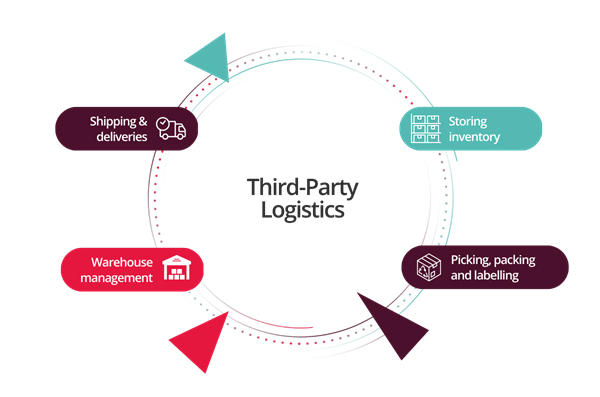

Outsourcing reverse logistics to a third-party logistics (3PL) partner

Outsourcing reverse logistics to a third-party logistics (3PL) partner can help companies overcome some of these challenges. 3PL providers have the expertise, resources, and technology to manage the entire reverse logistics process, from receiving the returned products to refurbishing them and reselling them. They can also help companies reduce costs, improve efficiency, and enhance customer satisfaction. However, outsourcing reverse logistics also has its own set of challenges. Companies must find a reliable and trustworthy 3PL provider that can meet their specific needs and requirements. They must also ensure that the 3PL provider has the necessary technology and software to manage the entire process efficiently and effectively. Additionally, outsourcing reverse logistics can result in loss of control over the process, which can lead to quality issues, delays, and other problems.

In summary, managing returns, repairs, and refurbishment internally can be complex and challenging, but it gives companies more control over the process. Outsourcing reverse logistics to a 3PL partner can help companies reduce costs, improve efficiency, and enhance customer satisfaction, but it also has its own set of challenges.

In summary, reverse logistics is an important capability for companies to have because it helps them reduce costs, create value, decrease risk, and complete the product life cycle. It also offers businesses an opportunity to meet sustainability targets and build customer loyalty.

What are some benefits of reverse logistics?

Reverse logistics is the process of managing the return, reuse, or disposal of products, materials, or components. Some of the benefits of reverse logistics are:

– It can lower costs by reducing transportation, administration, repair, and disposal expenses.

– It can improve customer satisfaction and loyalty by providing a positive and convenient return experience.

– It can enhance brand reputation and image by demonstrating social and environmental responsibility.

– It can increase revenue and profitability by reselling, refurbishing, or recycling returned products.

– It can optimize asset utilization and inventory management by recovering and reusing valuable materials and resources.

Understanding Your Needs:

When it comes to reverse logistics, it’s important to understand your company’s specific needs and requirements. Here are some factors to consider:

– Inventory types being returned: It’s important to know what types of products are being returned, whether they are whole products, parts, accessories, or other items.

– Volume of returns expected: Understanding the volume of returns you can expect will help you plan for the necessary resources and infrastructure to handle them.

– Return timelines/SLAs required: Knowing the expected return timelines and service level agreements (SLAs) will help you manage customer expectations and ensure that you have the necessary resources to meet those expectations.

– Return authorization and approval processes: Having clear and efficient return authorization and approval processes in place will help you manage returns more effectively and reduce the risk of fraud or abuse.

– Repair/refurbishment/remanufacturing requirements: Depending on the nature of the returns, you may need to repair, refurbish, or remanufacture the products. Understanding these requirements will help you plan for the necessary resources and infrastructure.

– Data tracking and reporting needs: Having the ability to track and report on returns data is critical for managing reverse logistics effectively. You should have a clear understanding of the data you need to track and how you will use that data to improve your reverse logistics processes.

By considering these factors, you can develop a reverse logistics strategy that meets your company’s specific needs and requirements.

Evaluating 3PL Partners for Reverse Logistics:

When evaluating third-party logistics (3PL) partners for reverse logistics, there are several factors to consider:

– Certifications: Look for 3PL providers that have relevant certifications, such as ISO or regulatory certifications, to ensure that they meet industry standards and requirements.

– Facilities: Consider the size, location, and capabilities of the 3PL provider’s facilities to ensure that they can handle your specific needs and requirements.

– Technology systems: Look for 3PL providers that have advanced technology systems, such as enterprise resource planning (ERP) integration and tracking software, to ensure that they can manage the entire reverse logistics process efficiently and effectively.

– Services offered: Consider the range of services offered by the 3PL provider, such as storage, repairs, refurbishment, and disposition, to ensure that they can meet your specific needs and requirements.

– Sustainability programs: Look for 3PL providers that have sustainability programs in place for end-of-life inventory, such as recycling or repurposing, to ensure that they align with your company’s sustainability goals.

– Customer references and reviews: Check customer references and reviews to get a sense of the 3PL provider’s reputation, reliability, and customer service.

By considering these factors, you can find a 3PL partner that meets your specific needs and requirements for reverse logistics.

Selecting the Right Partner:

When selecting a reverse logistics partner, it’s important to follow a structured process to ensure that you find the right partner for your needs. Here are some steps to consider:

1. Define evaluation criteria based on your needs: Before you start looking for a partner, you should define your evaluation criteria based on your specific needs and requirements. This will help you narrow down your search and find a partner that meets your needs.

2. Send RFPs and score responses: Once you have defined your evaluation criteria, you can send out requests for proposals (RFPs) to potential partners. You should score the responses based on your evaluation criteria to identify the best candidates.

3. Conduct site visits and audits: After you have identified the best candidates, you should conduct site visits and audits to evaluate their facilities, technology systems, and processes. This will help you get a better sense of their capabilities and ensure that they can meet your specific needs and requirements.

4. Negotiate contracts, SLAs, and pricing: Once you have selected a partner, you should negotiate contracts, service level agreements (SLAs), and pricing to ensure that you get the best possible deal. You should also ensure that the contract includes clear terms and conditions, as well as provisions for dispute resolution.

5. Consider transition/onboarding planning: Finally, you should consider transition/onboarding planning to ensure that the partnership gets off to a smooth start. This may include training, data migration, and other activities to ensure that the partner is fully integrated into your operations.

By following these steps, you can find a reverse logistics partner that meets your specific needs and requirements.

Managing the Relationship with a Reverse Logistics partner

Managing the relationship with a reverse logistics partner is critical to ensuring that the partnership is successful. Here are some best practices for managing the relationship:

– Communication protocols and escalations: Establish clear communication protocols and escalation procedures to ensure that issues are addressed promptly and effectively.

– Key performance metrics and reporting: Define key performance metrics and reporting requirements to ensure that the partner is meeting your expectations and delivering value.

– Continuous improvement processes: Implement continuous improvement processes to identify areas for improvement and drive innovation and efficiency.

– Contract reviews and renewals: Regularly review and renew contracts to ensure that they remain relevant and aligned with your needs and requirements.

By following these best practices, you can build a strong and successful partnership with your reverse logistics partner.

Key Takeaways for choosing the right 3PL for Reverse Logistics

1. Selecting the right third-party logistics (3PL) partner is crucial for effective reverse logistics operations.

2. Consider the partner’s expertise and experience in managing reverse logistics processes.

3. Evaluate the partner’s capabilities in handling product returns, repairs, refurbishments, and recycling.

4. Look for a 3PL provider with a robust technology infrastructure and tracking systems for real-time visibility.

5. Ensure the partner has a solid network and resources to handle your specific reverse logistics requirements.

6. Prioritize a 3PL partner that offers flexibility, scalability, and customized solutions to meet your evolving needs.

7. Collaborate closely with the chosen partner, maintaining clear communication and aligning goals and expectations.

8. Regularly assess the performance of your 3PL partner and make adjustments as needed to optimize reverse logistics efficiency.

Check out our previous post by clicking here: