Shipping containers have become a go-to choice for transporting goods worldwide. Their durability, security, and versatility make them ideal for a wide range of items, including hazardous materials. However, the handling and transportation of such materials require strict adherence to safety regulations to ensure their safe arrival at their destination without incident. In this article, we will explore key tips and best practices for navigating the world of shipping containers when dealing with hazardous materials, while highlighting key statistics and information to enhance our understanding of this critical aspect of

global trade.

Identifying Hazardous Materials

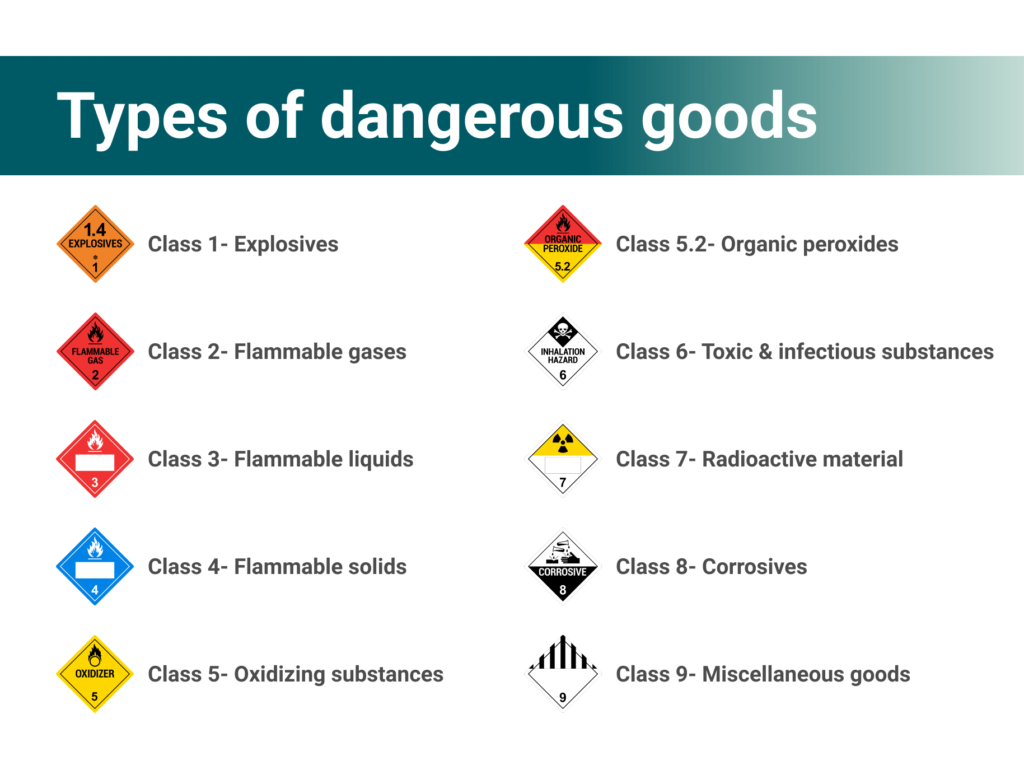

Before shipping any hazardous materials in a container, it is crucial to have a thorough understanding of the substances involved. This entails comprehending the chemical properties, potential hazards, and any special handling requirements of the material. Additionally, familiarity with the regulations and restrictions specific to the material being shipped, including labeling, packaging, and documentation requirements, is essential. Taking the time to accurately identify and classify hazardous materials is vital for safe handling and compliance with applicable regulations.

According to the United Nations, approximately 1.4 billion tons of hazardous goods are shipped globally each year. The transportation of hazardous materials is a critical component of numerous industries, including chemical manufacturing, pharmaceuticals, and energy production. It is estimated that hazardous materials account for around 10% of all cargo shipped globally. This highlights the significance of proper handling procedures to mitigate the risks associated with these materials.

Choosing Appropriate Containers and Packaging

Selecting the appropriate container and packaging is paramount when shipping hazardous materials. The container material must be compatible with the specific hazardous material being transported and capable of withstanding potential hazards, such as pressure changes or temperature fluctuations. For instance, corrosive substances may require containers made of materials that resist corrosion, while flammable materials may necessitate containers that can withstand high temperatures.

The packaging itself should be designed to prevent leaks or spills during transportation. It should also be clearly labeled with the appropriate hazard warnings and handling instructions. Notably, inadequate packaging can lead to dire consequences. In 2015, a warehouse explosion in Tianjin, China, resulted in at least 173 deaths and caused widespread damage. The disaster was attributed to the improper storage of hazardous materials, including an inadequate choice of packaging materials[^3^]. To avoid such catastrophic incidents, adherence to regulations and guidelines regarding container and packaging selection is crucial.

Labeling and Marking for Safety

Properly labeling and marking shipping containers is a critical aspect of handling hazardous materials. Clear and accurate labeling ensures that containers are handled and transported safely and that emergency responders are aware of potential hazards in case of accidents. Key information that should be included on labels and marks includes the UN number, proper shipping name, hazard class, and packing group. This information aids in identifying the nature of the materials and facilitates appropriate emergency response measures.

In the United States, the Department of Transportation (DOT) regulates the labeling and marking of hazardous materials shipments through the Hazardous Materials Regulations (HMR)[^4^]. The HMR establishes comprehensive guidelines for labeling and marking hazardous materials shipments, ensuring uniformity and clarity in the transportation industry. Compliance with these regulations is essential to prevent mishandling or misidentification of hazardous materials, safeguarding both workers and the general public.

Loading and Unloading Procedures

Following proper loading and unloading procedures is crucial to minimize the risk of accidents and spills when handling hazardous materials in shipping containers. This involves utilizing appropriate equipment and protective gear, such as gloves and goggles, to protect workers from potential harm. It is also essential to ensure that the container is properly secured during transport to prevent it from shifting or falling, which could lead to leaks or spills.

In 2019, the International Maritime Organization (IMO) reported a total of 173 incidents involving hazardous and noxious substances during the maritime transportation of dangerous goods[^5^]. Proper loading and unloading procedures, along with adherence to safety regulations, are fundamental in reducing the frequency and severity of such incidents.

Moreover, the condition of shipping containers plays a crucial role in ensuring the safe transport of hazardous materials. Regular inspection and maintenance are essential to identify and address any structural weaknesses or potential risks that may compromise the integrity of the container during transit. The International Convention for Safe Containers (CSC) sets forth international standards for container safety, including periodic inspections to assess their suitability for use[^6^]. Compliance with these standards ensures the safety and reliability of shipping containers.

Employee Training and Preparedness

Properly training all employees involved in the handling and transportation of hazardous materials is a vital step in ensuring their safe shipment in containers. Training should cover the specific types of hazardous materials being transported, as well as the appropriate handling and safety procedures associated with them. Employees should also receive training on emergency response procedures to effectively deal with spills or accidents.

Regular refresher training is crucial to keep employees up-to-date on the latest regulations and best practices for handling hazardous materials. The hazardous materials industry is subject to evolving regulations and advances in safety practices, necessitating ongoing education for all personnel involved.

According to a report published by the International Labour Organization (ILO), an estimated 651,000 deaths occur annually due to hazardous substances, including those encountered during transportation[^7^]. This highlights the need for comprehensive training programs to mitigate risks and safeguard workers’ well-being. Companies should prioritize investing in employee training to ensure the safe and compliant handling of hazardous materials in shipping containers.

Handling hazardous materials in shipping containers requires meticulous planning, proper documentation, labeling, and adherence to established handling procedures. Compliance with international regulations is essential to minimize the risk of accidents and protect both people and the environment. Rigorous employee training, regular container inspections, and well-defined emergency response procedures are integral components of safe hazardous material transportation. By giving careful attention to established safety protocols, shipping hazardous materials can be accomplished with minimized risks and increased safety.

As the global economy continues to rely on the efficient movement of goods, understanding and implementing proper handling procedures for hazardous materials in shipping containers is crucial. While shipping containers offer great convenience and versatility, their misuse or inadequate handling can have severe consequences. Therefore, it is incumbent upon all stakeholders involved, including shippers, regulators, and employees, to prioritize safety, compliance, and ongoing education in this critical domain of global trade.

Check out our Blog for more logistics insights, tips and news